STANDARD AND CUSTOM SOLUTIONS

PRODUCTIVITY AND EFFICIENCY

Applications

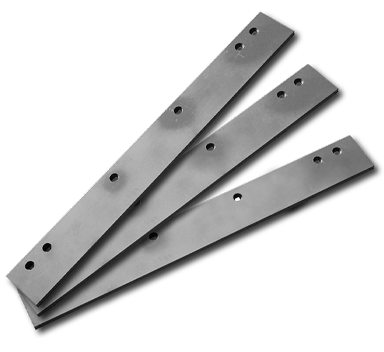

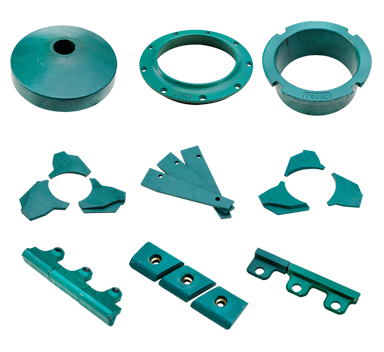

KoneCarbide Tool provides tungsten carbide products and solutions

for a variety of industries including:

About Us

Chengdu Kone Carbide Tool Co. Ltd is an international trade company that specializes in research and development, production, customization, and marketing of tungsten carbide tools and blanks for mining & construction, oil & gas, snow removal and more industries.